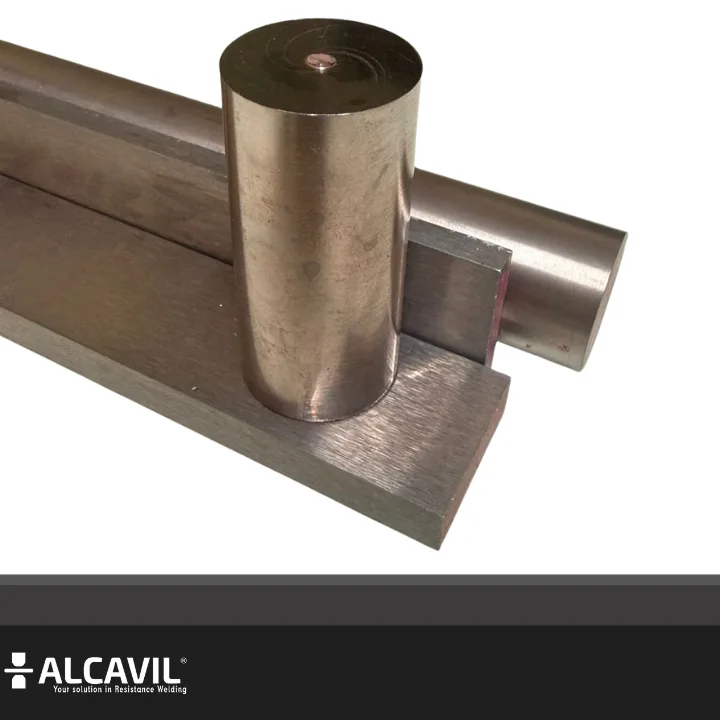

ALCAVIL

ALCAVIL was founded in in Monterrey, when a group of field engineers identified a systemic failure in the automotive supply chain: suppliers delivered electrodes with metallurgical inconsistency and poor machining tolerances, causing unplanned line stoppages.

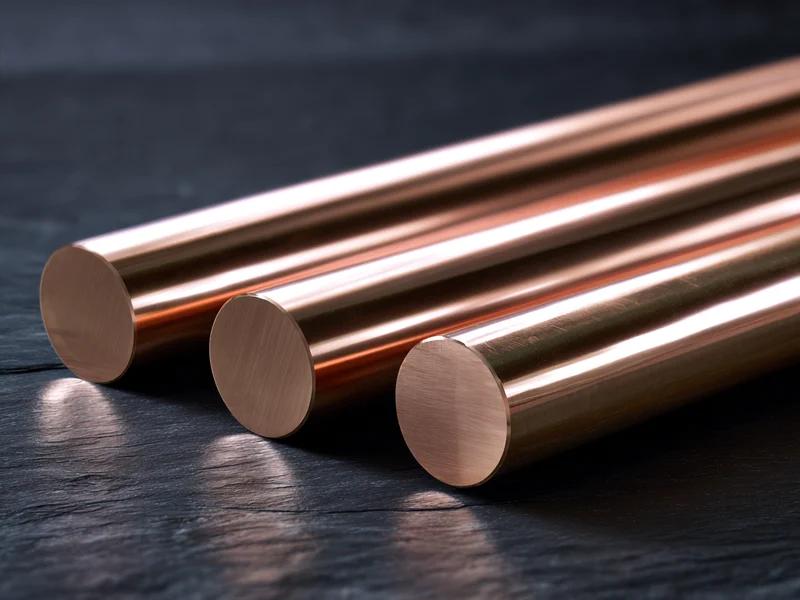

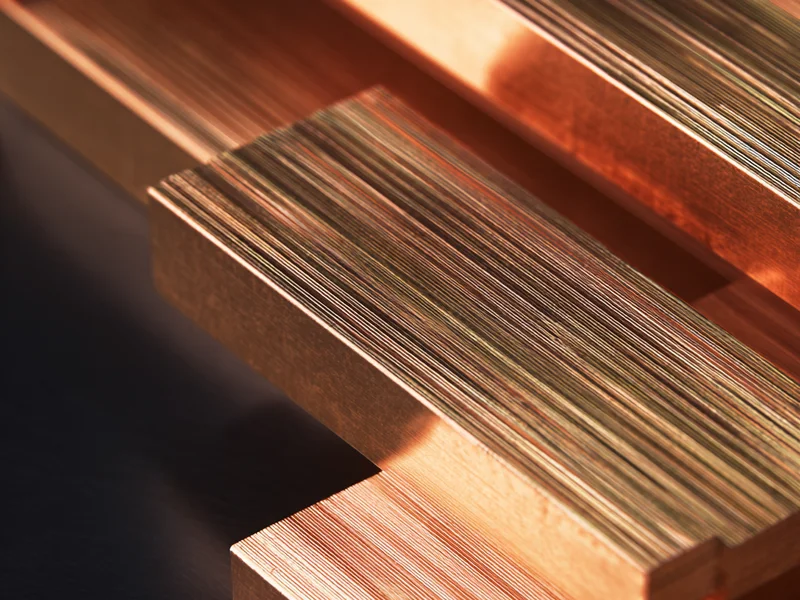

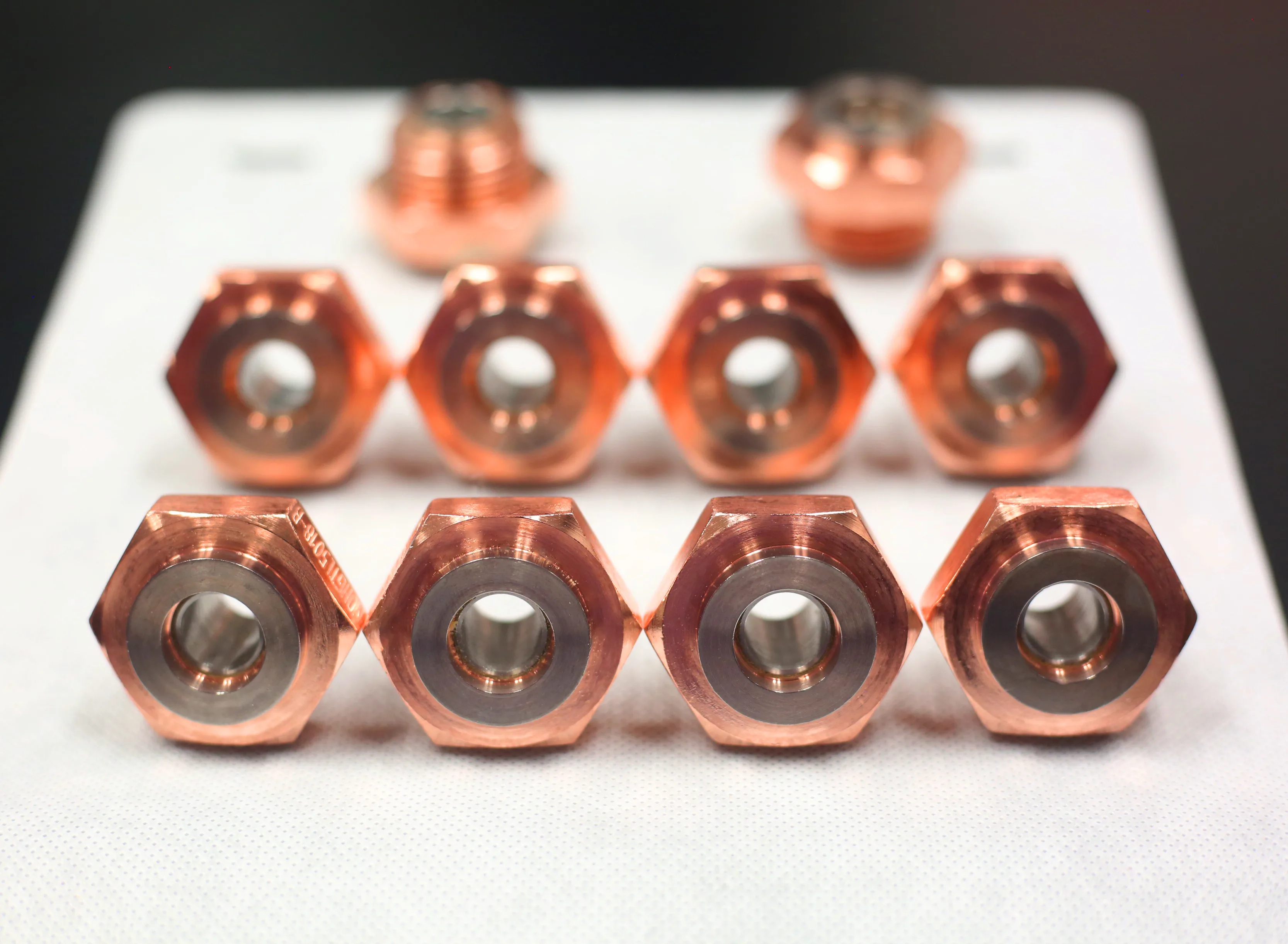

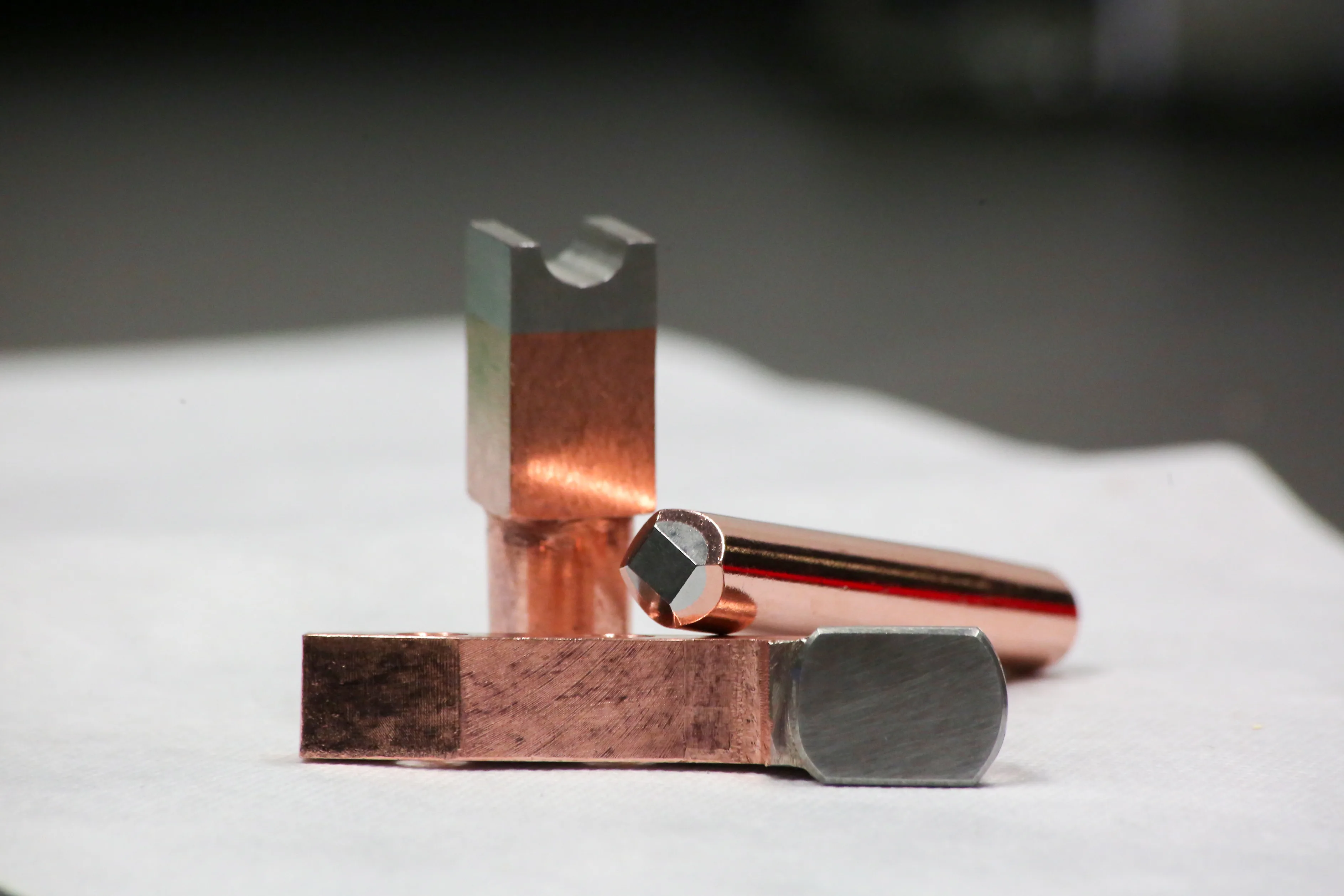

We are not middlemen. We are a machine shop specialized in resistance welding consumables, understanding the needs, workflows and standards this process demands. We integrate the value chain by directly importing certified raw materials to guarantee traceability from foundry to your assembly line.

Every electrode we manufacture meets RWMA/AWS J1.3 specifications. We work with Class 1, 2 and 3 alloys to satisfy the requirements of OEM, Tier 1 and Tier 2 in automotive, aerospace and appliance sectors.