Nut Welding, Stud Welding & Projection Welding

Projection, Nut and Stud Welding

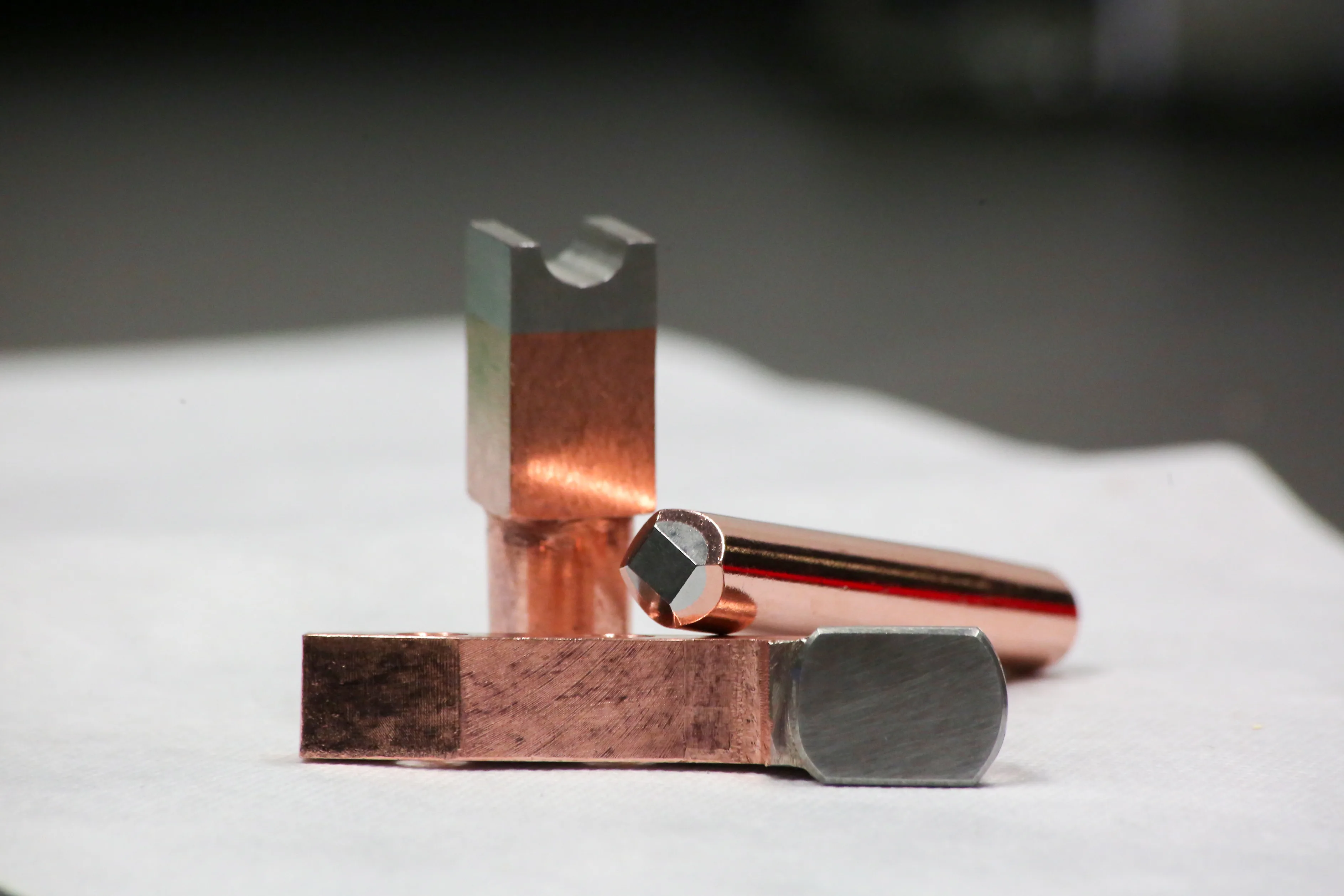

Specialized electrodes for nut welding, stud welding and studs in automotive production lines. We manufacture from the electrode body to the refractory insert, all under one roof.

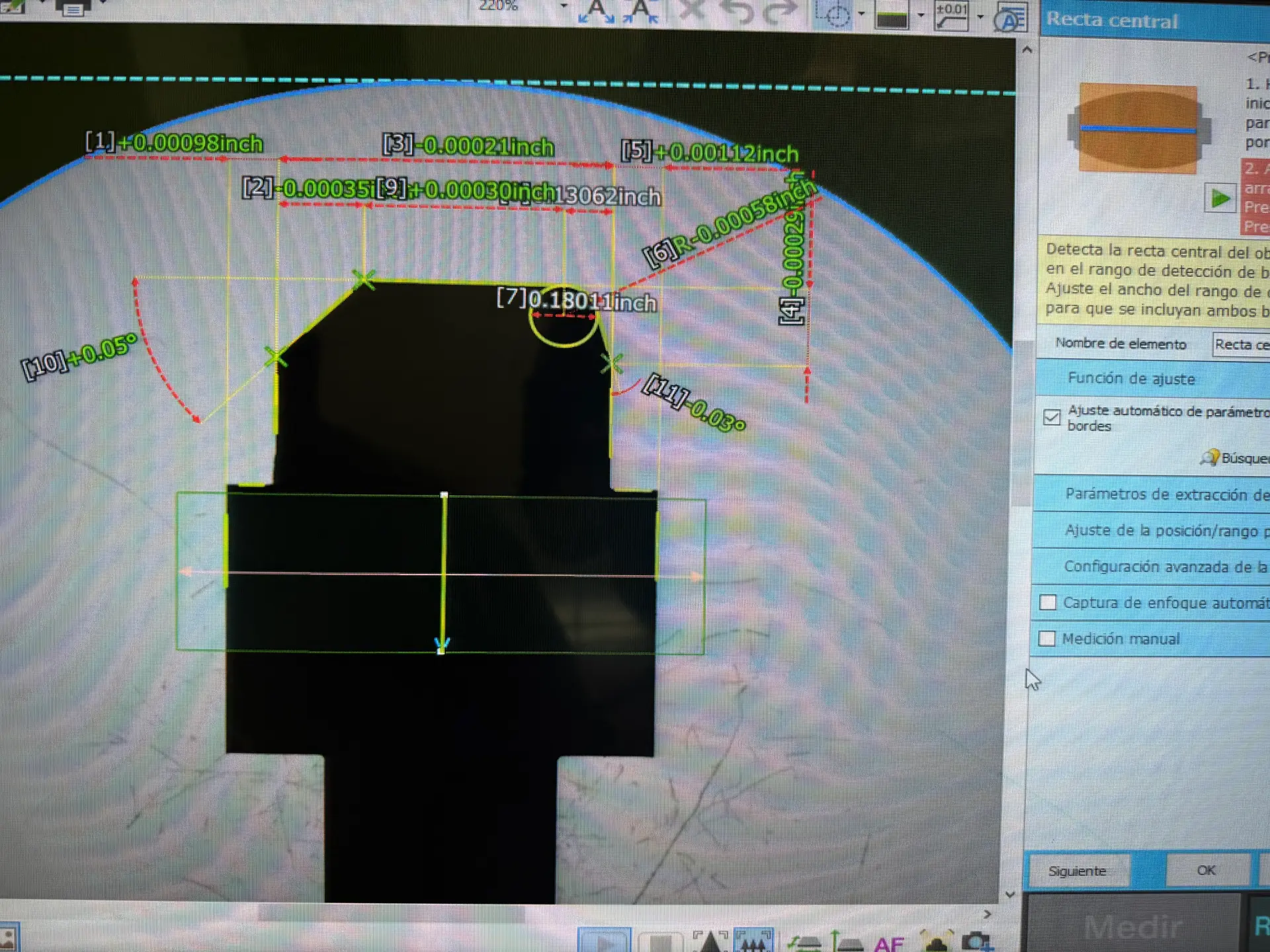

Projection welding concentrates the current at specific points through preformed protrusions in the part, enabling high-strength joints in M4-M12 nuts, studs and automotive structural components.

- Electrodes with CuW Insert (Class 10-12) High-strength brazing with silver alloy for maximum conductivity and impact resistance

- Ceramic Guide Pins (Zirconia, Si3N4) and KCF Insulating - precise centering, low spatter adhesion, maximum service life

- Stainless Steel Pins Economical, absorb impacts without breaking - require electrode with insulating bushings

- Threaded Electrodes and Bases In-house manufacturing of holders and bases for quick change

- Shunts / Flexible Connectors Braided cables and connectors for current bypass

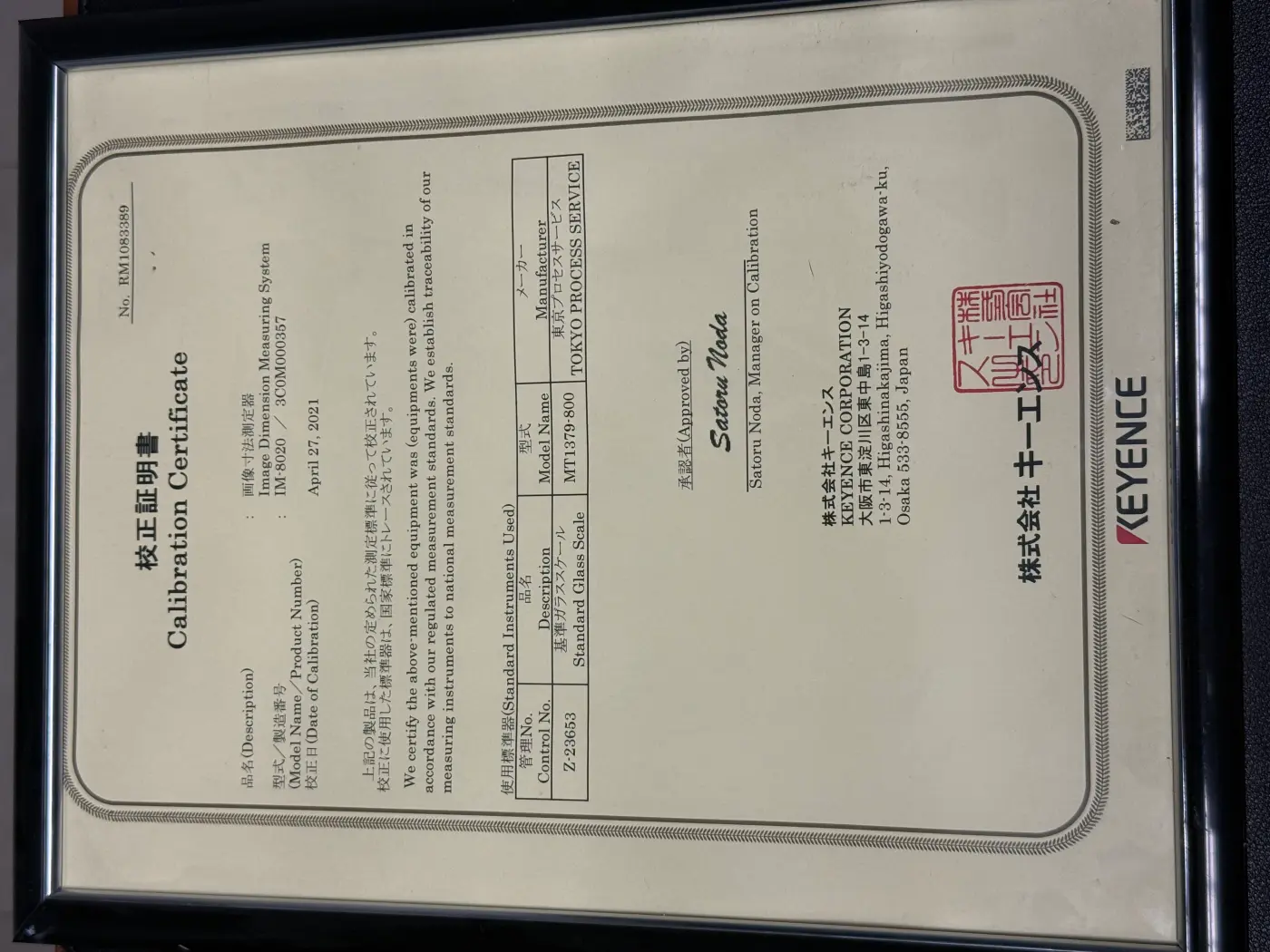

Technical Differentiator - AWS J1.3

Superior Metallurgical Bond: Elkonite inserts (CuW Classes 10-12 per AWS J1.3) brazed with silver alloy ensure continuous electrical conductivity and mechanical resistance to repeated impact.