Elkonite Copper-Tungsten (CuW) Sales in Mexico

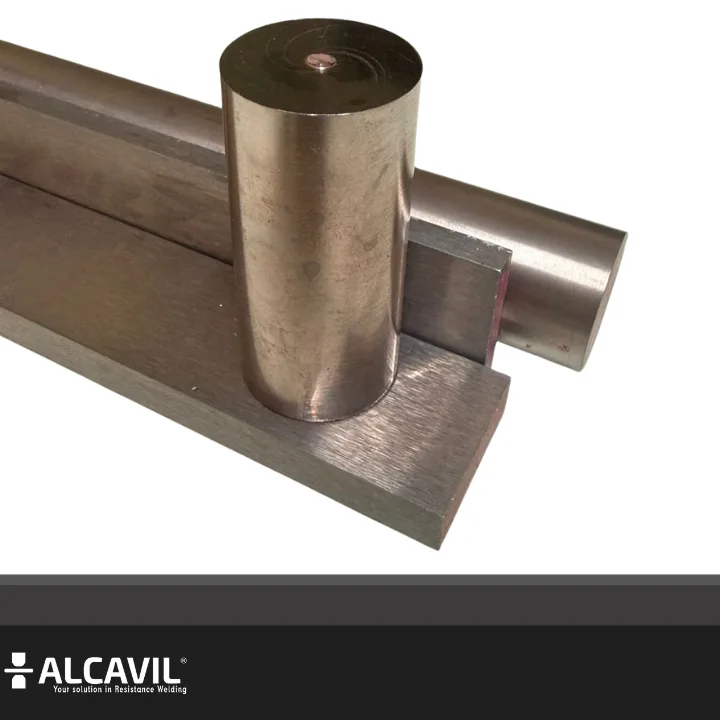

Copper-tungsten composite for high thermal demand applications. The industry standard for nut projection welding, die facings and faced electrodes where copper alloys don't hold up.

Applicable standards: AWS J1.3 • RWMA Class 10, 11, 12

ALCAVIL is a leading supplier of Elkonite Copper-Tungsten (CuW). Classes 10, 11 and 12 for nut and stud projection welding. Permanent stock in Monterrey. Request quote →

Available Grades by RWMA Class

Higher tungsten content means higher hardness and wear resistance, but lower conductivity. Select based on your application severity.

Elkonite® 5W3

Standard ProjectionElkonite® 10W3

Most UsedWhen to use Elkonite vs Copper Alloys?

Use Copper-Tungsten when copper alloys (Class 2 or 3) wear quickly or deform from temperature. Typical cases: nut projection on steel, high volume production (>1000 pieces/day), or when the electrode can't cool adequately between cycles.

Note on Trademarks and RWMA Classification

Elkonite® is a registered trademark of CMW Inc. (formerly Contact Metal Welding). Similar to how "Kleenex" became synonymous with facial tissues, "Elkonite" has become the generic name for Copper-Tungsten composites in the resistance welding industry. Values shown are typical manufacturer values, not AWS J1.3 minimums. AWS specifies composition ranges: Class 10 (43-47% Cu), Class 11 (23-27% Cu), Class 12 (18-22% Cu).

When NOT to Use Elkonite/CuW (and What to Use Instead)

Elkonite is the most expensive material — only use it when truly justified.

❌ Don't use Elkonite/CuW if:

- Class 3 already works well for you — If your Class 3 electrodes have good life in projection, don't spend more.

- It's standard spot welding — For spot welds, copper alloys (Class 2 or 3) are more suitable. CuW is for projection and inserts.

- The problem is setup, not wear — Elkonite won't fix misconfigured parameters or misalignment. Validate your process first.

- The electrode DEFORMS, doesn't wear — If it's getting "crushed" instead of losing material, it's a parameter or pressure issue, not material.

📋 Plant Examples:

- M8 projection with C17510, electrodes last 800 welds → Acceptable life. Elkonite would be over-engineering. Continue with Class 3.

- M10 projection with Class 3, electrodes last only 200 welds and look worn → That DOES justify Elkonite 10W3. Tungsten resists abrasive wear better.

✓ Use this instead:

- Class 3 (C17510/C18000) — If you have moderate wear in projection but C3 still works.

- Class 2 (C18200) — If it's standard spot welding on steel.

⚡ 30-Second Checklist:

- □ Does Class 3 last less than 300 welds in projection? → Consider Elkonite

- □ Is it normal spot welding? → You DON'T need Elkonite

- □ Does the electrode crush/deform? → Check parameters first

- □ Welding non-ferrous materials (Al, Cu)? → Elkonite may help

Not sure if Elkonite is worth it for your application? Tell us your current electrode life and we'll help you decide if the upgrade is justified →

What We See in Real Applications

- 10W3 (Class 11) is the standard: It's what we use most for nut and stud projection. The 75% tungsten / 25% copper balance works well for most applications.

- 30W3 (Class 12) for contacts: With 80% tungsten, it's used more for conductive components like electrical terminals than for welding.

- 5W3 (Class 10) is rare: In our experience, it's rarely used - most applications work better with 10W3.

- Wear vs deformation: If your electrode wears (loses material), Elkonite helps. If it deforms (gets crushed), it may be a parameter issue.

If you're unsure which grade you need, 10W3 is the recommended starting point for projection.

Comparison Table - Elkonite® Family

| RWMA Class | Grade | Composition | % IACS | Hardness | Density |

|---|---|---|---|---|---|

| — | 1W3 | 45% Cu / 55% W | 53 | 79 HRB | 12.6 g/cm³ |

| — | 3W3 | 32% Cu / 68% W | 50 | 88 HRB | 13.93 g/cm³ |

| Class 10 | 5W3 | 30% Cu / 70% W | 48 | 90 HRB | 14.18 g/cm³ |

| Class 11 | 10W3 | 25% Cu / 75% W | 46 | 98 HRB | 14.70 g/cm³ |

| Class 11/12 | 20W3 | 22% Cu / 78% W | 44 | 99 HRB | 14.80 g/cm³ |

| Class 12 | 30W3 | 20% Cu / 80% W | 42 | 103 HRB | 15.4 g/cm³ |