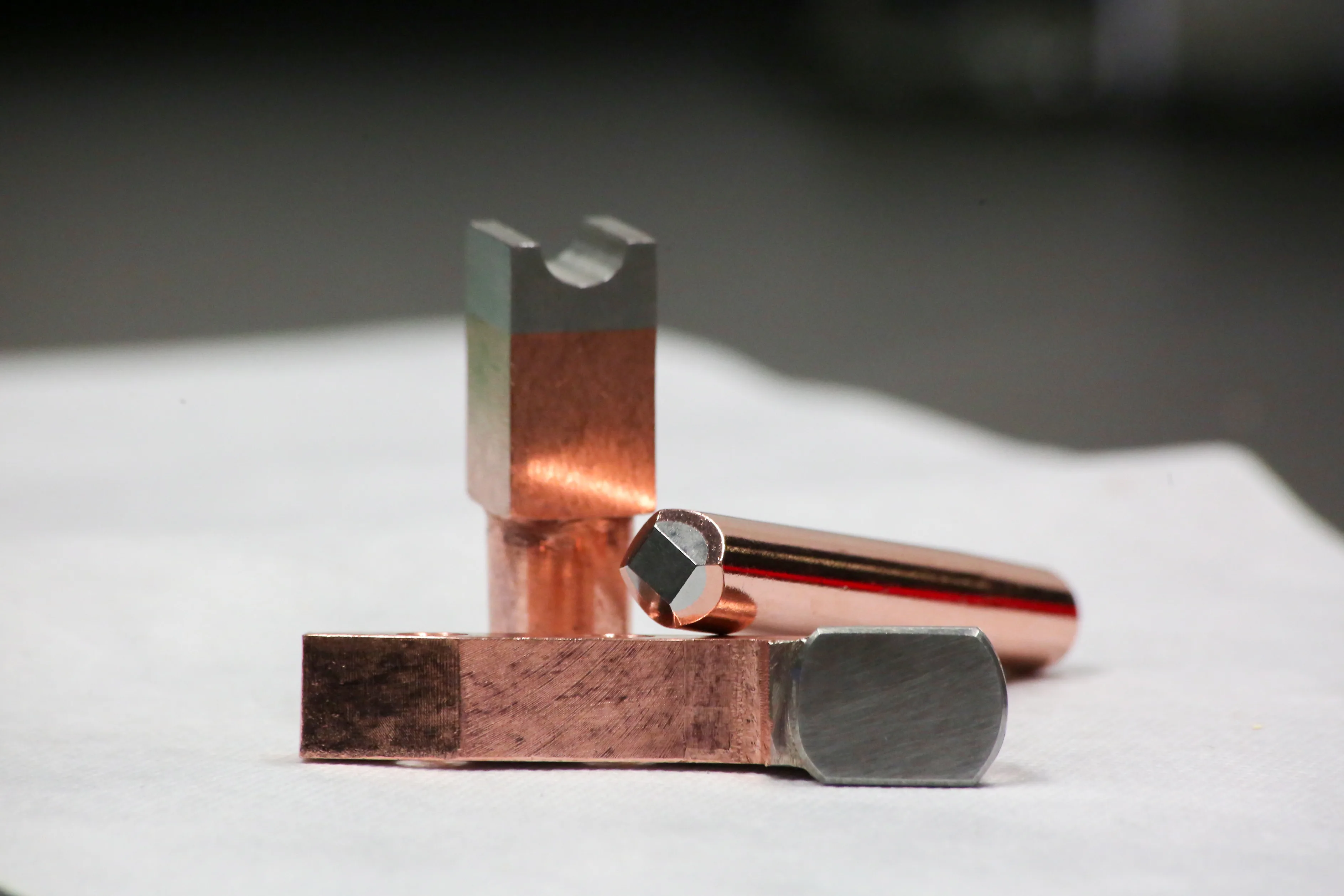

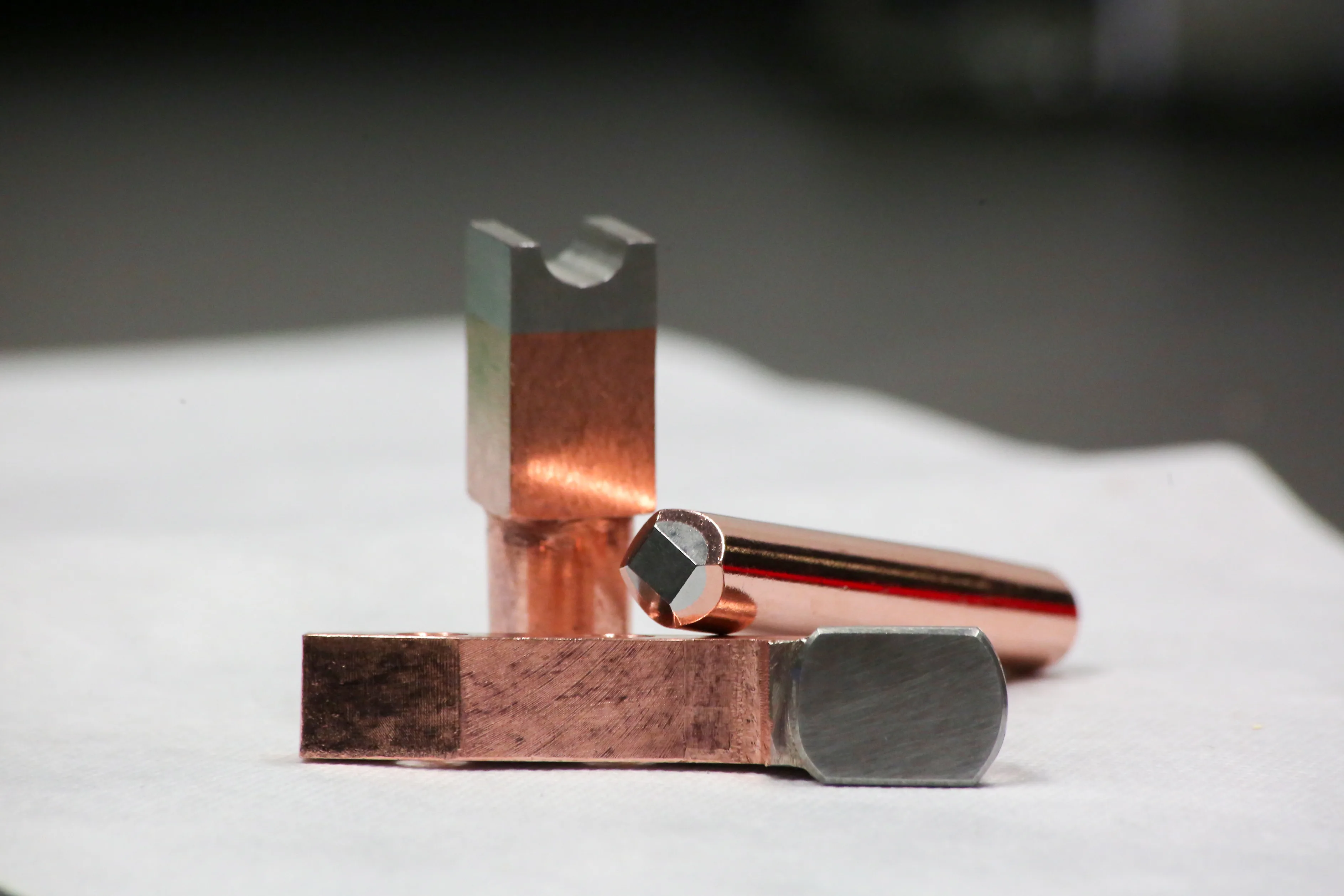

Refractory Metal Faced Electrodes · RWMA Class 13 and 14

Tungsten and Molybdenum Insert Electrodes

Refractory material electrodes for welding copper terminals, silver contacts and electrical components. Precision EDM machining and certified metrology.

What are Insert Electrodes?

Refractory Metal Faced Electrodes are specialized electrodes that use tungsten (RWMA Class 13) or molybdenum (RWMA Class 14) at the contact face. These materials have extremely high melting points and do not stick to molten copper.

They are essential for electrical contact welding, copper terminals, contactors, switches and electrical switchgear. Typical customers include manufacturers like Siemens, Schneider Electric, Phoenix Contact and BorgWarner.

Available Products

- Tungsten Electrodes (W, WLa10, WLa15, WLa20) Pure and lanthanated tungsten for copper terminals in motors and electrical components. Higher hardness and wear resistance. WLa15 and WLa20 recommended for 24/7 production.

- Molybdenum / TZM Electrodes Mirror finish available for silver contacts without marks. TZM (Ti-Zr-Mo) for higher high-temperature resistance. More economical than tungsten with excellent performance.

- Elkonite (CuW) Electrodes Copper-Tungsten for precise parameter control in special applications. Combines copper conductivity with tungsten hardness.

- Morse Taper 1 and Morse 2 Standard mounting for medium frequency (MFDC) electrical contact welding equipment. Compatible with Milwaukee and similar equipment.

Technical Differentiator – AWS J1.3

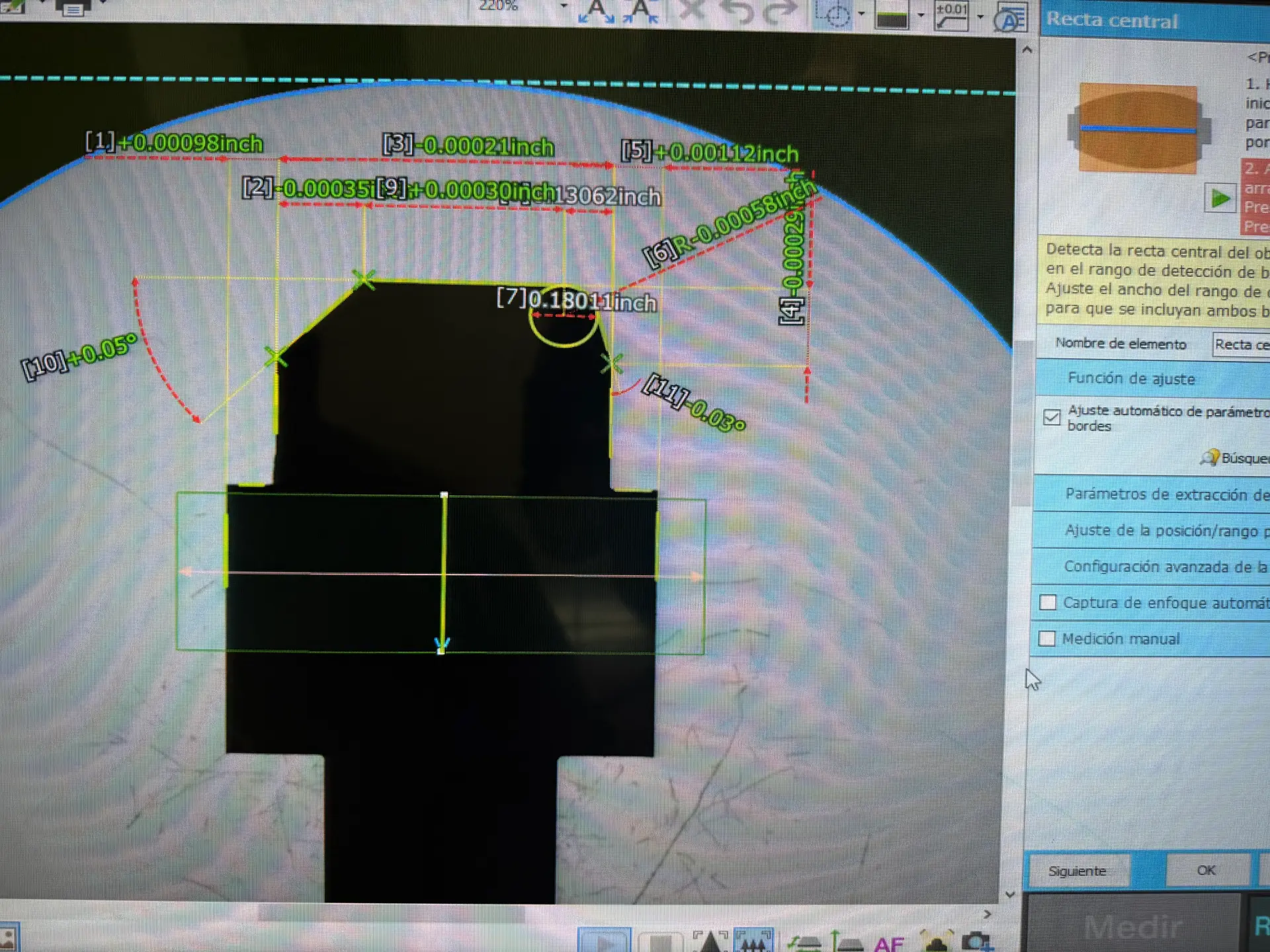

Micrometric Precision: Our Class 13 tungsten and Class 14 molybdenum electrodes are manufactured with EDM machining to avoid fractures in the brittle material. Mirror finish on molybdenum eliminates marks on silver contacts. High-precision metrology equipment verifies tolerances on each part.

Manufacturing Capabilities

EDM Machining

Precision electrical discharge machining for tungsten. The material is brittle and requires EDM cutting to avoid fractures and achieve tight tolerances.

Computerized Metrology

High-precision optical measurement system to verify dimensions and tolerances on each manufactured electrode.

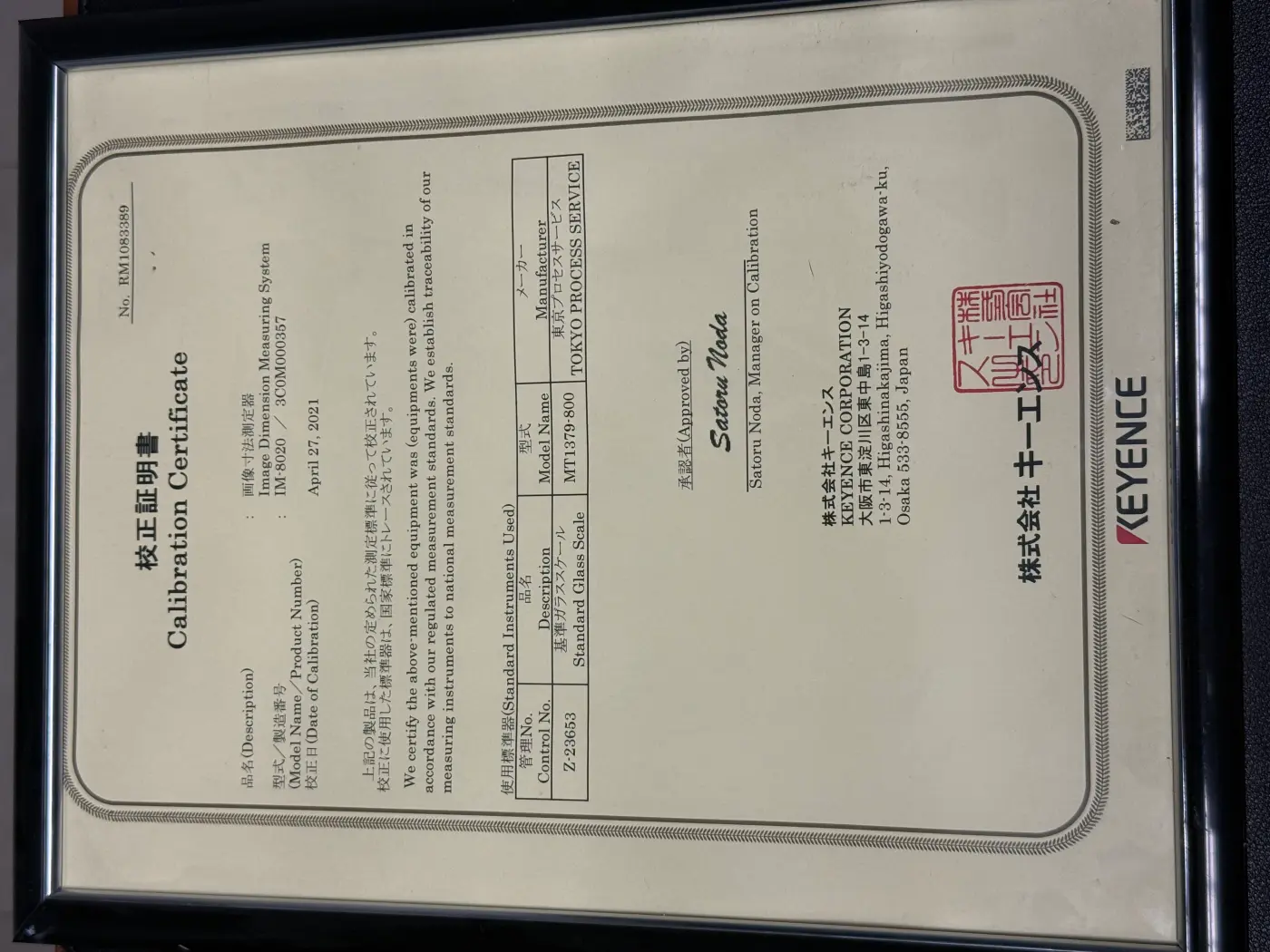

Certified Equipment

Our measuring equipment has current calibration certificates that guarantee the precision of each part.

Applications

- Copper Terminals Terminal welding in electric motors, automotive harnesses and power components.

- Silver Contacts Contact joining in relays, contactors and switches. Mirror finish on Mo for zero marks.

- Switches and Switchgear Switchgear and medium/low voltage electrical distribution components.

- Electronic Components Precision welding in power electronics and industrial control components.

Tungsten Types

We offer pure and lanthanated tungsten per ISO 6848:

- WP (Green) - Pure Tungsten 99.95% For low-volume basic applications. Economical but shorter service life.

- WLa10 (Black) - 1% Lanthanum Oxide For medium-volume terminals. Better starting and stability than WP.

- WLa15 (Gold) - 1.5% Lanthanum Oxide High-volume production. Ideal replacement for WTh20 (thoriated) without radiation.

- WLa20 (Blue) - 2% Lanthanum Oxide Intensive 24/7 production. Maximum service life and consistency in demanding applications.