AWS J1.3 Technical Specifications

| Property | Value | Unit |

|---|---|---|

| UNS Designation | C17200 | - |

| Composition | Cu + 1.8-2.0% Be + 0.2% Co | % wt |

| Electrical Conductivity | ≥22 | % IACS (AWS J1.3 min) |

| Hardness | ≥33 | HRC (AWS J1.3 min) |

| Tensile Strength | 1100-1400 | MPa |

| Softening Temperature | 650 | °C |

| Elastic Modulus | 128 | GPa |

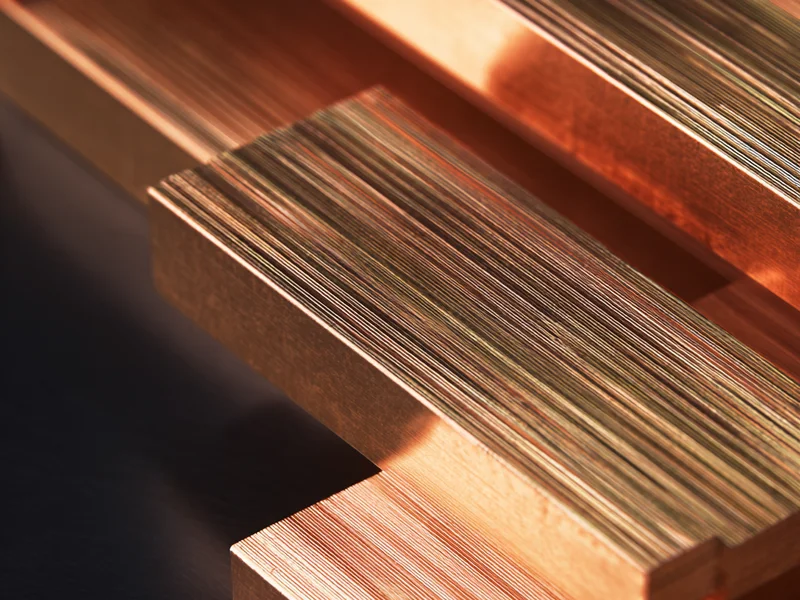

Specific Applications

Class 3 vs Class 4: The Critical Difference

Both classes contain beryllium, but have completely different purposes:

| Property | Class 3 (CuNiBe C17510) | Class 4 (CuBe C17200) |

|---|---|---|

| Conductivity | 45-60% IACS | 22-25% IACS |

| Hardness | 96-102 HRB | 36-42 HRC |

| Primary Use | Direct contact electrodes | Molds, fixtures, dies, tooling |

| Balance | Conductivity + Hardness | Maximum hardness, lower conductivity |

Class 3 maintains sufficient conductivity to be the contact electrode. Class 4 sacrifices conductivity for maximum mechanical strength, used in components that are not the main electrode.

Important: Class 4 is NOT for electrodes

It's common for Class 4 to be confused with an electrode material for resistance welding. It's not.

- If you're looking for welding electrodes: Class 4 is not what you need. Use Class 1, Class 2 or Class 3 depending on your application.

- Conductivity is too low: With only 22% IACS, Class 4 doesn't conduct enough current to be an effective electrode.

- It's much more expensive: The high beryllium content (1.8-2.0%) makes it significantly more costly than other classes.

Class 4 is designed for tooling, molds and inserts where extreme hardness and heat transfer are needed, but not main electrical current conduction.

What We See in Real Applications

In our experience:

- Plastic injection molds: This is where Class 4 is most used. The combination of hardness and thermal conductivity allows rapid cooling cycles.

- Mold inserts: Specific areas that require accelerated cooling or wear resistance.

- Tooling and fixtures: Structural components that need to withstand mechanical loads without deformation.

- Common confusion: Sometimes we receive requests for "Class 4 for electrodes" - we always validate the application because almost always what they need is Class 2 or 3.

If you're unsure which class you need, let's discuss your application to recommend the right material.